VACON® NXC

With protection, it is the compact frequency inverter that operates reliably in aggressive conditions of, for example, the mining, fuel and gas or water and wastewater sectors. The thermally managed protection extends the life of the frequency inverter and guarantees trouble-free operation.

Features & advantages

- Low investment costs since no additional design, engineering or cooling fans are required

- Start-up and reduced maintenance time thanks to simple access control compartments and removable keyboard

- Improved maintenance thanks to the mounting rails and the maintenance concept with extraction templates

- Lower maintenance costs thanks to the rugged and proven design

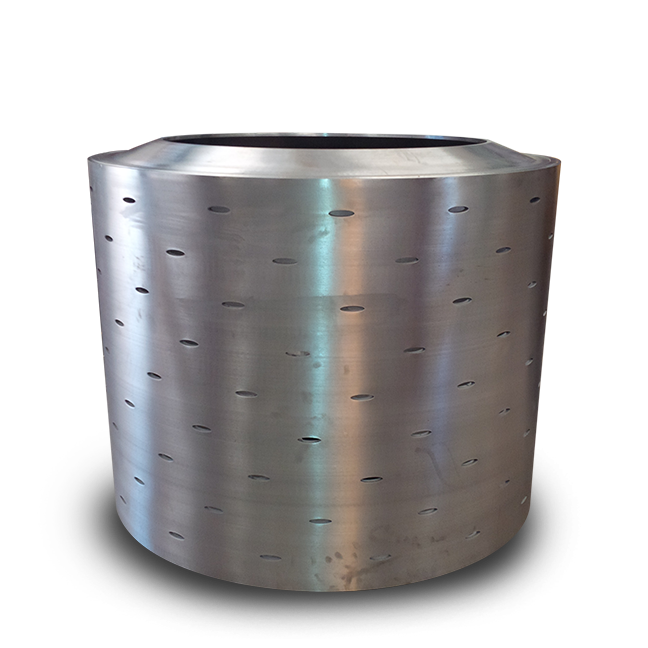

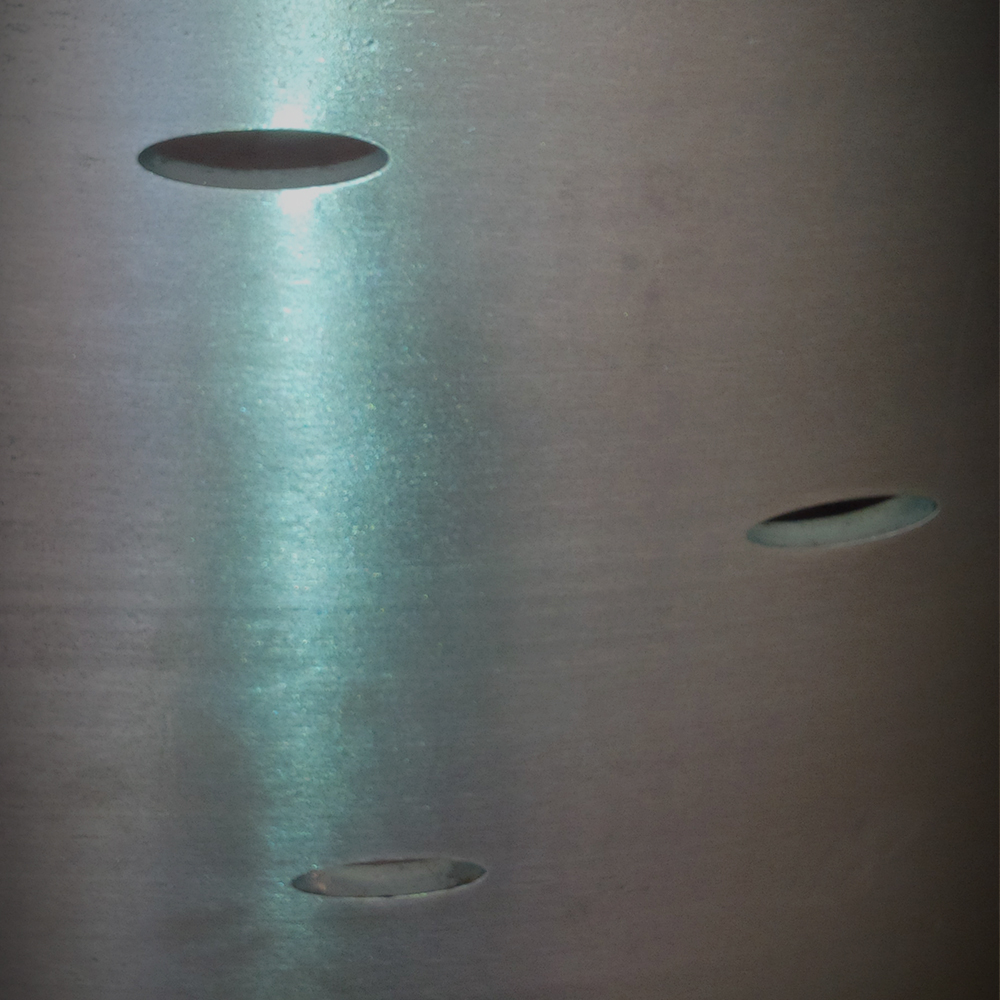

BATCH CENTRIFUGE MODELS: NXC 150, 200, 250, 300 Y 350 HP (REGENERATIVES)

CONTINOUS CENTRIFUGE MODELS: VLT 75, 100, 125 Y 150 HP

PARKER

The AC690 + series is a single range of AC drives designed to meet the needs of all single-speed single-speed variable speed motor applications through the most sophisticated multi-unit integrated systems. The heart of the AC690 + is an engine control model based on a very advanced 32-bit microprocessor. This provides an exceptional dynamic performance platform to which a large number of communications and control options can be added, allowing you to adapt the units to meet your exact needs. The AC690 + is available in 380-500V 3-phase from 0.75 to 1000kW and 220V-240V 0.75 to 55kW.

BATCH CENTRIFUGE MODELS: AC690 150, 200, 250, 300 Y 350 HP

CONTINUOUS CENTRIFUGE MODELS: AC10 75, 100, 125 Y 150 HP

ABB

With the unique ACS880 frequency converters, it simplifies your world and opens up to all possibilities. Enjoy complete flexibility and capacity with converters for wall mounting or cabinet installation. You can customize everything according to your specific needs in sectors such as oil and gas, mining, metals, chemicals, cement, power plants, material handling, pulp and paper, cutting and maritime applications. Built on the common platform of ABB converters for all types of applications, such as cranes, extruders, winches, winders, conveyor belts, mixers, compressors, pumps and fans.

MAIN FEATURES

- Intuitive control panel and PC

- toolDirect torque control (DTC) for accurate control in open and closed loop

- Integrated security features for simplified configuration

- Communication with the main automation networks

- Removable memory unit for easy commissioning and replacement of the drive

- Energy optimizer and energy efficiency information for monitoring and energy saving

- Designed to facilitate service

BATCH CENTRIFUGE MODELS: ACS880 (REGENERATIVE)